Case Studies

Case Studies

Challenging Case Studies.

Problems and their Solutions.

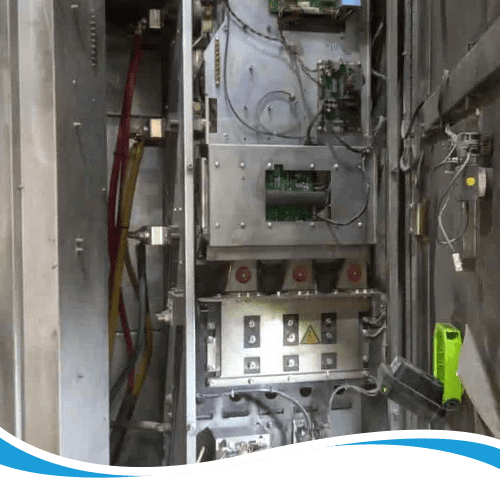

Case Study – Plywood Manufacturing

Drive cleaning avoids fire

The Problem

Drive Cooling Air circulation circuit found to have been hanging open which was found during routine maintenance causing all the plywood dust to enter the Drive.

Flammable Plywood dust in high voltage electric circuit is a Fire Hazard. Drive failure due to over temperature caused by choked Heat sinks.

The Solution

Cleaned out Drive with specialised vacuum and fixed the Cooling Air Circuit securing drive from similar situation in future.

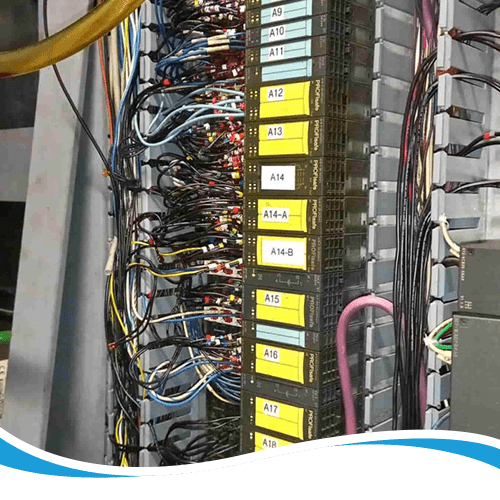

Case Study – Waste Recycling

Complete plant shutdown due to faulty

E-stop circuit

The Problem

Complete plant shut down for over 8 hours with site electrical engineer on leave and the site engineer not able to trace the problem.

The Solution

Central Group traced out the faulty E-stop circuit. The function was temporarily disabled allowing the plant to operate over night. The customer was advised to fix the E-stop wire break as soon as possible.

Electrical drawings were not available at the site. Central traced out the problem without any drawings.

Case Study – Utilities – Water

Quick response ensures water continues to flow in Welsh village

The Problem

AnyDrive356 received a call from a client with a request to help with the repairs to a burst pipe.

A team of four engineers immediately attended the site, taking one of Central’s Hire Fleet with them.

The Hire Fleet comprises drives from 2.2KW up to 400KW, and on this occasion a drive was hired to run a 4-20 signal on the pressure transducers.

The Solution

The action taken by Central Group’s team ensured the work to the burst pipe could continue without affecting the water supply to the residents of the town.

All work was completed in a period of six hours, from initial call out to final solution.

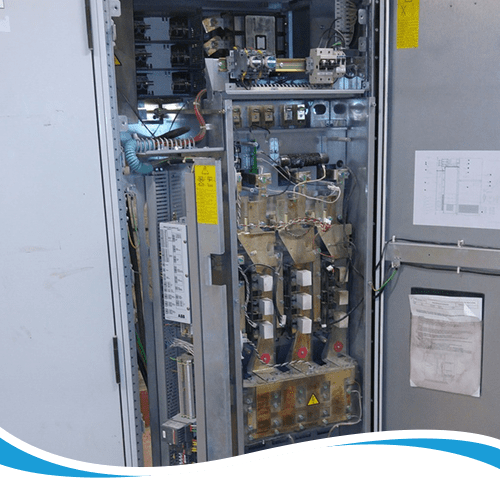

Case Study – Construction

Drive gets back up and running

The Problem

At 9am on Easter Sunday, Central Group received a call from Hanson Cement in Mold.

The site’s electrical engineer was calling to report that the site was down due to a 250kw drive failing.

The Solution

Central’s Service Manager went straight to the workshop where a identical, spare drive was loaded onto the van and taken to the site.

The old drive was removed to be repaired and the spare drive installed and commissioned.

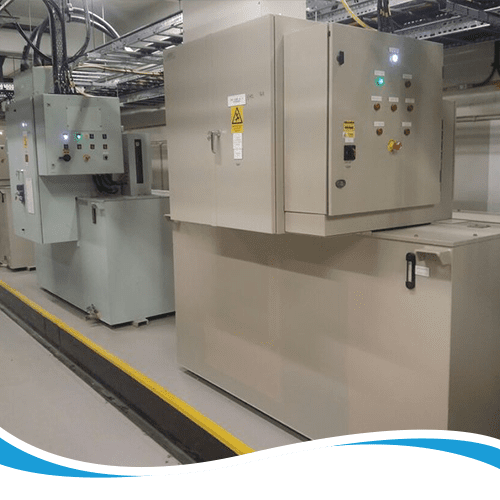

Case Study – Maintenance

Smooth running at Cambridgeshire site

The Problem

Central Group was recently contacted by the Environment Agency with a request to visit to one of their pumping stations to test and service three resistance starters.

Kennett Pumping Station is based in Cambridgeshire and pumps water between the River Ouse and two local reservoirs. A maintenance visit was required to check and overhaul several pieces of equipment at the site.

As a UK distributor of AOIP products, Central was able to service the units and replace the oil and chemicals in all three of the 2600kw, 11,000volt starters.

The Solution

The job was completed quickly and efficiently over a period of three days, ensuring minimum disruption on site and the continued smooth running of the site’s motor units.